Description

BYK® leveling agents

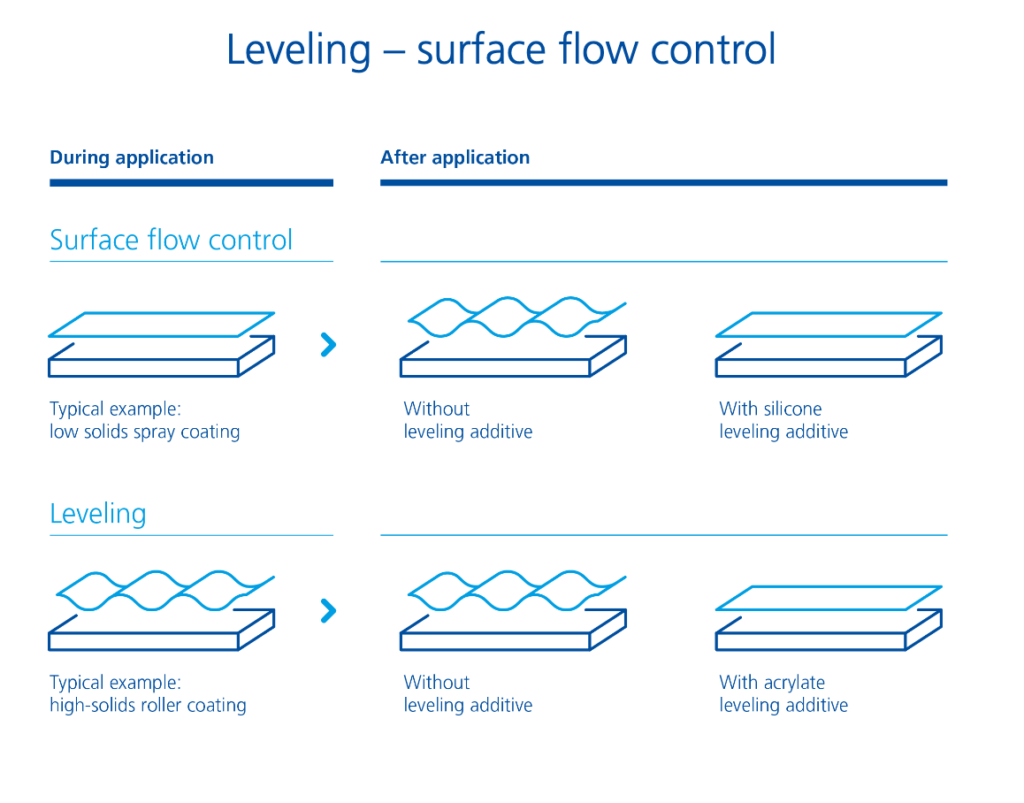

BYK Leveling Agents represent a transformative solution for achieving impeccable surface quality in various coating applications. Designed to address the challenges of unevenness and imperfections, these agents offer unparalleled performance across a broad spectrum of formulations.

With a commitment to innovation and quality, BYK Leveling Agents are tailored to meet the diverse needs of manufacturers, providing solutions for both solvent-based and water-based systems. From automotive coatings to architectural paints, these agents deliver exceptional results, contributing to enhanced durability and customer satisfaction.

Utilizing advanced technology and expertise, BYK Leveling Agents excel in minimizing surface irregularities, such as orange peel, cratering, and streaking, resulting in a smooth and uniform finish. Whether applied to paints, varnishes, or other coatings, these agents ensure consistent leveling and optimal appearance, enhancing the overall aesthetic appeal of the finished product.

Technical Specification

|

Type

|

Product description

|

|

|---|---|---|

| BYK® -381 | Polyacrylates | Ionic solution of a polyacrylic copolymer. Acts as an acrylic leveling agent for aqueous systems. Offers improved levelling. Provides increased gloss. Prevents surface defects such as craters and pinholes. Exhibits no effect on surface tension. Used in industrial coatings, automotive top coats and primer surfacers, wood and furniture coatings and in speciality coatings. |

| BYK® -325 | Silicone-based | Solution of a polyether modified methylalkylpolysiloxane copolymer. Acts as a silicone based leveling agent for solvent-borne and aqueous coatings. Offers improved flow and leveling. Gives partial defoaming properties. Provides a slight reduction of surface tension. Prevents Bénard cell formation. Also prevents ghosting (wipe-marks) if recoated with the same paint. Does not causes rewetting problems and does not influences recoatability. Used in solvent-borne and aqueous coatings. |

| BYK® -352 | Polyacrylates | Solution of a polyacrylate. Acts as an anti-crater amnd leveling agent for solvent-borne and solvent-free coatings. Improves leveling (long wave) and gloss. Offers degassing properties. Provides very wide compatibility with many coating systems. Produces a long wave effect and avoid cratering in the system. Does not negatively influences recoatability or intercoat adhesion. Reduces surface tension slightly. Used in solvent-borne and solvent-free coatings. |

| BYK® -326 | Sillicones | BYK® -326 by BYK is a solution of a polyether-modified polymethylalkylsiloxane. Acts as a good levelling agent. It slightly reduces surface tension. Exhibits high transparency, improved substrate wetting, and mild defoaming properties in epoxy clear coatings for flooring. It does not crystallize under -18°C, which makes it easy to use at low temperatures. Offers broad compatibility and maintains high transparency of most clear coating systems. BYK® -326 is used in automotive, solvent-borne, aqueous and 100% coating applications. Complies with REACH regulation (EC) No. 1907/2006. The usage level of the product is 0.05-0.5%. |

| BYK® -355 | Polyacrylates | BYK® -355 by BYK is a solution of polyacrylate. Acts as an acrylic based leveling agent for solvent-borne and solvent-free coatings. Improves levelling and gloss. Produces a long wave levelling performance. Avoids cratering. BYK® -355 provides slight reduction in surface tension. Used in industrial coatings, OEM and automotive refinish formulations and coil coatings. |

| BYK® -356 | Polyacrylates | Solvent-free polyacrylate. Acts as an anti-crater and leveling agent for formulations of resin masterbatches for powder coatings. Does not causes hazing in pigmented systems. Improves leveling (long wave). Does not influences intercoat adhesion. Avoids cratering. Used in industrial coatings, OEM and automotive refinish formulations, coil coatings and powder coatings |

| BYK® -364 P | Polyacrylates | Polyacrylate, adsorbed on silicon dioxide. Acts as a polar anti-crater and leveling agent to improve pigment and subtrate wetting of powder coatings. Improves leveling of powder coating systems, and prevents orange peel. Also prevents other surface defects such as craters and fisheyes. Improves DOI (distinction of image) and reduce pinholes at the surface of the coating. Used for powder coatings. |

| BYK® -323 | Silicone-based | Polymethylalkyl-methylaralkyl-siloxane. Acts as a silicone based flow and leveling agent for solvent-borne coatings. Offers improved flow and leveling. Displays partial defoaming properties. Exhibits no or only slight foam stabilization. Does not increases intercoat adhesion when overcoated. Possesses heat resistancy upto 250°C. Orients the flatting agent in flat topcoats and in multi-coat systems. Prevents the formation of Bénard cells. Used in industrial and wood & furniture coatings. |

| BYK® -354 | Polyacrylates | Solution of polyacrylate. Acts as an anti-crater and leveling agent for solvent-free and solvent-borne systems. Improves leveling and gloss. Provides a long wave levelling performance. Avoids cratering. Reduces surface tension slightly. Displays degassing properties. Shows a very wide compatibility with many coating systems. Exhibits thermal stability. Used in solvent-borne and solvent-free coatings and in printing inks, overprint varnishes. |

| BYK® -3750 | Sillicones | BYK® -3750 by BYK is a SVHC label-free, surface additive that acts as flow and leveling agent, wetting- and anti-blocking agent. It is a solution of a polyether-modified polydimethylsiloxane. It increases slip and gloss. It prevents the formation of Bénard cells. It exhibits broad compatibility. It is designed for solvent-borne systems. It is suitable for food contact coatings. |

| BYK® -UV 3575 | Leveling agent | BYK-UV 3575 by BYK is a solution of a multi-acrylic functional modified polydimethylsiloxane. Also recommended for solvent-free and aqueous coating systems. Acts as a wetting- & leveling agent. It crosslinks with radiation-curable systems and thereby produces long-lasting effects without migrating. Used in tripropylene glycol diacrylate (TPGDA) based solvent-borne coating system. |

| BYK® -392 | Polyacrylates | Solution of a polyacrylate. Acts as an anti-popping agent for solvent-borne systems. Due to its non-polar structure it acts as a defoaming and air release agent. Gives good activity in airless/airmix systems. Improves leveling and gloss. Slightly reduces surface tension. Used in solvent-borne and solvent-free coatings. |

| BYK® -085 | Sillicone-based | Polymethylalkylsiloxane. Acts as a silicone based defoamer and surface additive for solvent-borne systems. Prevents foam and bubble formation. Offers improved leveling. Provides increased surface slip. Does not causes dewetting or defects in intercoat adhesion when recoated. Used in solvent-borne coatings. |

| BYK® -322 | Sillicone-based | Aralkyl modified methylalkyl polysiloxane. Acts as a silicone based leveling additive for solvent-borne coatings. Provides slight surface tension reduction. Possesses partial defoaming properties. Improves flow and leveling. Prevents the formation of Bénard cells. Exhibits thermal stablility at baking temperatures up to 250°C. Does not normally stabilizes foam. Used in solvent-borne coatings. |

| BYK® -3902 P | Polyacrylates | Polyacrylate, adsorbed on silicon dioxide. Acts as a new innovative leveling additive for powder coatings. Improves leveling and gloss in powder coatings, due to its very good dispersibility. |

| BYK® -3566 | Sillicones | BYK®-3566 by BYK is silicone and polyether macromer-modified polyacrylate. It acts as a surface additive that can combine good leveling with anti-cratering properties, especially in aqueous systems. It offers improved surface energy. It is suitable for coating/air interface in solvent-borne & 100 % UV systems. |

PRODUCT SPECIFICATION

Product name:

CAS No.

Standard Package:

Container Loading: 25 kg

Hazard class: Class 8

Delivery time: up to 30 days